28 мм даими магнитлы редукторлы баскыч моторы капкачын көйләргә мөмкин

Тасвирлама

Бу - диаметры 28 мм булган, ышкылу муфтасы белән тышка чыгарылган тизлекле двигатель.

Бу моторның тизлек нисбәте 16:1, 25:1, 32:1, 48.8:1, 64:1, 85:1 тәшкил итә.

Моторның адым почмагы 5,625°/64 тәшкил итә һәм ул 1-2 фазалы кузгату яки 2-2 фазалы кузгату белән эшли.

Номиналь көчәнеш: 5VDC; 12VDC; 24VDC

мотор тоташтыру чыбыгы һәм тоташтыргыч чыбык спецификацияләре UL1061 26AWG яки UL2464 26AWG,

Мотор, нигездә, сантехника җиһазларында, термостатик клапанда, кайнар су кранда, акыллы унитазда, кондиционерда, су температурасын һәм агымын автоматик рәвештә көйләүдә, ишек йозагында, су чистарткычта һәм берничә көнкүреш техникасы сериясендә кулланыла.

Шулай ук, төгәл контроль таләп итә торган башка өлкәләрне дә гамәлгә ашырырга мөмкин. Ачык цикллы контрольне гамәлгә ашыру аркасында, позицияләрне арзанрак контрольдә тоту гамәлгә ашырыла.

Бу продуктның бәясе югары җитештерү күләме аркасында башка продуктларга караганда түбәнрәк булырга мөмкин.

Моннан тыш, аның өслегендә шестерня бар, гомуми шестерня материалы POM (пластик), без аны металл шестерня белән дә алыштыра алабыз, ләкин бу бәясен арттырачак.

Әгәр дә сез безнең продуктлар белән кызыксынсагыз, теләсә кайсы вакытта минем белән элемтәгә керә аласыз.

Параметрлар

| Көчәнеш (В) | Каршылык(Ω) | Тарту моменты 100PPS (мН*м) | Тоткарлау моменты (мН*м) | Йөкне бушату ешлыгы (PPS) |

| 5 | 18 | ≥98 | ≥29.4 | ≥500 |

| 12 | 60 | ≥117 | ≥29.4 | ≥500 |

| 12 | 70 | ≥68.7 | ≥29.4 | ≥500 |

| 24 | 200 | ≥68.7 | ≥29.4 | ≥500 |

| 24 | 300 | ≥58.8 | ≥29.4 | ≥500 |

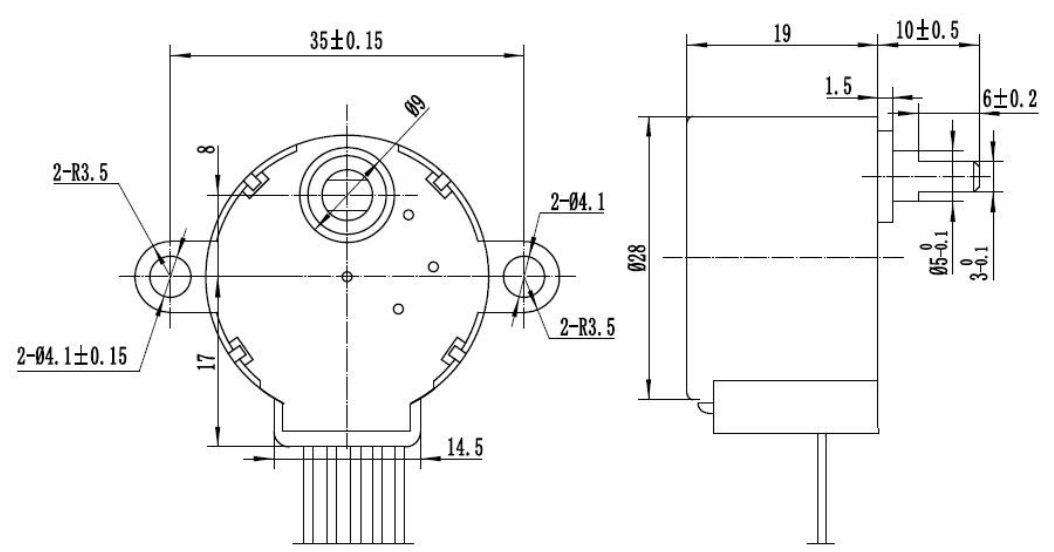

Дизайн рәсеме: Чыгару валын көйләү

көйләнергә мөмкин булган ltem'нар

Тешле нисбәте,

Көчәнеш: 5-24В,

Тешле материал,

Чыгу вал,

Мотор капкачының дизайнын көйләргә мөмкин

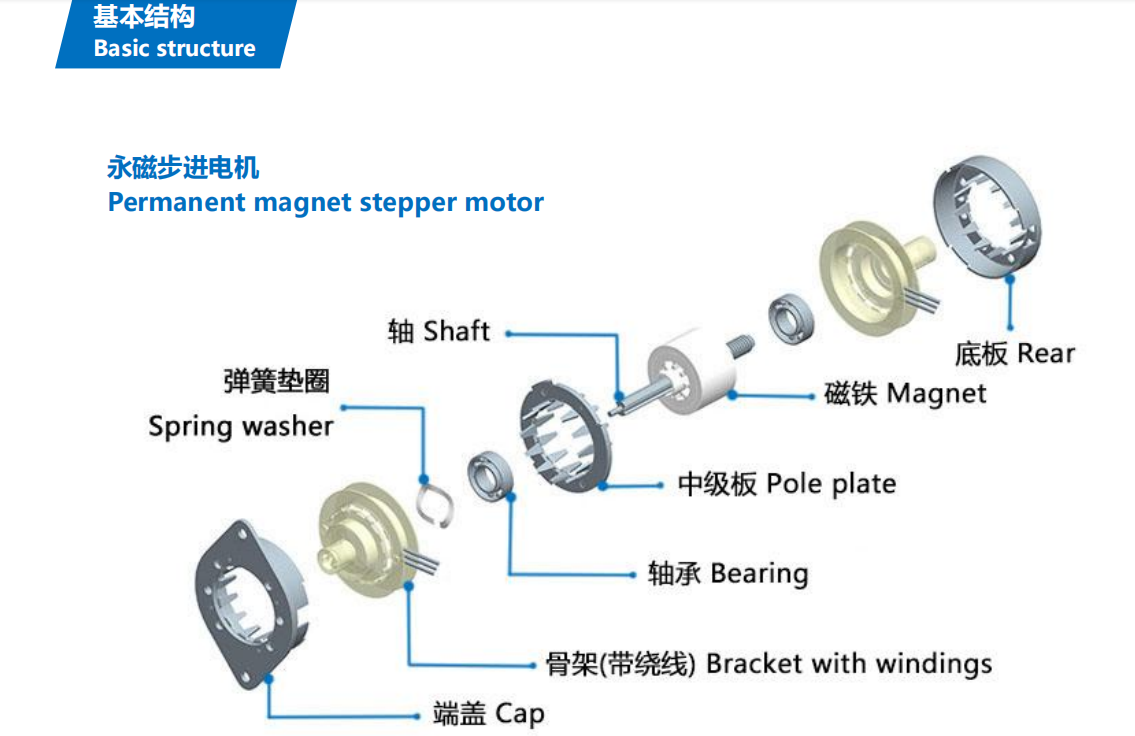

PM адым моторының төп төзелеше турында

Функцияләр һәм өстенлекләр

1. Югары төгәллекле позицияләү

Степперлар төгәл кабатланырлык адымнар белән хәрәкәт иткәнлектән, алар төгәллек таләп итә торган кушымталарда бик яхшы эшлиләр.

позицияләү, мотор хәрәкәт иткән адымнар саны буенча

2. Югары төгәллекле тизлек контроле

Хәрәкәтнең төгәл адымнары шулай ук процесс өчен әйләнү тизлеген бик яхшы контрольдә тотарга мөмкинлек бирә

автоматизация һәм робототехника. Әйләнү тизлеге импульслар ешлыгы белән билгеләнә.

3. Пауза һәм тоту функциясе

Привод белән идарә итү мөмкинлеге булганда, моторның блоклау функциясе бар (мотор чыбыклары аша ток үтә, ләкин

мотор әйләнми), һәм тоту моменты әле дә бар.

4. Озак гомер һәм түбән электромагнит комачаулау

Адымлы моторның щеткалары юк, һәм аны щетка белән алыштырырга кирәкми, щетка белән чистартылган кебек.

Даими ток двигателе. Щеткаларның ышкылуы юк, бу хезмәт итү вакытын арттыра, электр очкыннары юк һәм электромагнит комачаулауны киметә.

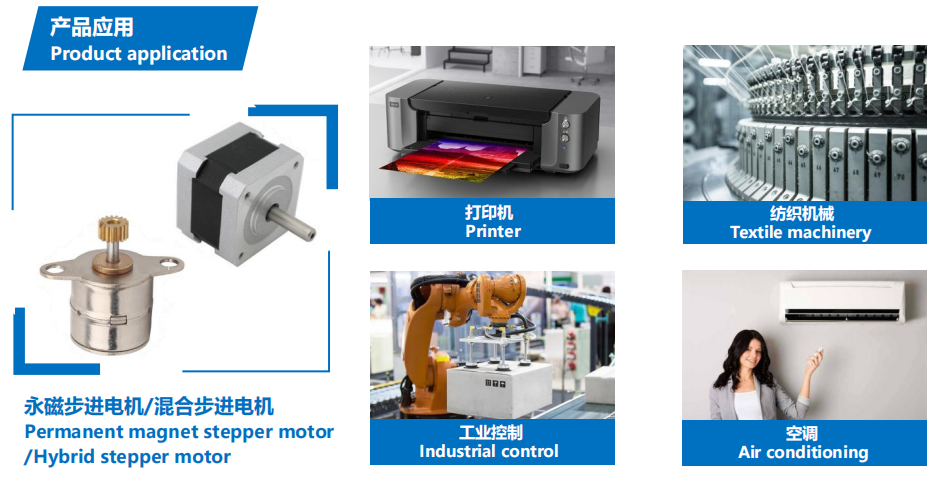

PM адым моторын куллану

Принтер,

Текстиль җиһазлары,

Сәнәгать контроле,

санитария җиһазлары,

термостатик клапан,

кайнар су краннары,

Су температурасын автоматик рәвештә көйләү

Ишек йозаклары

Кондиционер

Су чистарту клапаны һ.б.

Адымлы моторның эш принцибы

Адымлы моторның эшләве программа тәэминаты белән идарә ителә. Мотор әйләнергә тиеш булганда, эшләткеч

адым моторы импульсларын кулланыгыз. Бу импульслар адым моторын билгеләнгән тәртиптә энергия белән тәэмин итә, шуның белән

мотор роторының билгеле бер юнәлештә (сәгать теле юнәлешендә яки сәгать теле юнәлешенә каршы) әйләнүенә китерә. Шулай итеп

моторның дөрес әйләнүен тәэмин итү. Двигательдән импульс алган саен, ул адым почмагы белән әйләнәчәк (тулы адымлы привод белән), һәм моторның әйләнү почмагы привод импульслары саны һәм адым почмагы белән билгеләнә.

Алып бару вакыты

Әгәр бездә үрнәкләр булса, без үрнәкләрне 3 көн эчендә җибәрә алабыз.

Әгәр бездә складта үрнәкләр булмаса, без аларны җитештерергә тиеш, җитештерү вакыты якынча 20 календарь көн.

Күпләп җитештерү өчен, заказ бирү вакыты заказ күләменә бәйле.

Упаковка

Үрнәкләр күбек губкага һәм кәгазь тартмага төрелә, экспресс аша җибәрелә

Күпләп җитештерү, моторлар тышы үтә күренмәле пленка белән гофрланган картоннарга төрелә. (һава юлы белән җибәрү)

Диңгез аша җибәрелсә, продукт паллетларга төреләчәк

Түләү ысулы һәм түләү шартлары

Үрнәкләр өчен, гомумән алганда, без Paypal яки Alibaba кабул итәбез.

Күпләп җитештерү өчен без T/T түләүләрен кабул итәбез.

Үрнәкләр өчен, без җитештерү алдыннан тулы түләүне җыябыз.

Күпләп җитештерү өчен, без җитештерү алдыннан 50% алдан түләүне кабул итә алабыз, ә җибәрү алдыннан калган 50% түләүне җыя алабыз.

Без заказны 6 тапкырдан артык бергә эшләгәннән соң, без башка түләү шартлары турында сөйләшә алабыз, мәсәлән, A/S (күргәннән соң)

Түләү ысулы һәм түләү шартлары

1. Редукторлы адымлы моторларның сәбәпләре:

Статор фазасы тогы ешлыгын үзгәртүче адым моторы, мәсәлән, адым моторы привод схемасының керү импульсын үзгәртү кебек, түбән тизлекле хәрәкәткә әйләндерә. Түбән тизлекле адым моторы адым командасын көткәндә, ротор тукталыш халәтендә була, түбән тизлекле адымда тизлек тирбәнешләре бик зур булачак, бу вакытта, мәсәлән, югары тизлекле эшкә күчү, тизлек тирбәнешләре проблемасын хәл итә ала, ләкин момент җитмәячәк. Ягъни, түбән тизлек момент тирбәнешләренә китерәчәк, ә югары тизлек момент җитмәячәк, редукторлар куллану кирәк.